JVS Engineers (JVS Flow Control) provides after-market with involvement of engineering solutions.

- To provide onsite service, installation and commissioning of newly manufactured equipment.

- To provide onsite re-certification of High Pressure Well Control Manifolds, underneath piping and diverter system as CEM by executing design and engineering activities.

- To provide After Sales support for Spares Parts, on line trouble shooting and certification.

- To provide onsite modification, installation and commissioning & testing of existing High Pressure Well Control Manifolds (onshore & offshore) as per customer need.

JVS Flow Control has 3 Service bases worldwide. Singapore, India and Houston. These 3 Service Bases cover all our clients worldwide. Our service team have at least 10 years of relevant product knowledge in Field Engineering. Our value proposition is to provide Fast and effective response in planning and executing offshore recertification of the High Pressure Well Control Manifold. Our Field Engineers have performed Onsite Recertification of manifolds on Tender barge to 6th Generation Drill Ships. By performing the onsite 5 Year Recertification, we have proven to reduce the cost of up to 70% in cost of performing the recertification of through the conventional way.

Furthermore, under the guidelines of API, JVS Flow Control is able to be the Current Equipment Manufacturer of other OEM equipment. This enable JVS Flow Control to completely take over the management of the Manifold and to recertify the manifold under JVS Flow Control API Licence.

JVS Scope includes performing the site survey to capture all the information and converting the information into a 3D model, providing the tools, consumables and equipment to safely recertify the manifold offshore.

With our Global Footprint and API Licienced plants located worldwide, JVS keeps an inventory of spares so as to support our clients operating in that region. This greatly reduces our response time to the rig. JVS Flow Control also keeps a log of the inventory onboard the rig. Our clients are able to access these information and copies of their Manufacturing Data Packages through our online portal which is accessable 24/7 & worldwide.

List of services provided to valued customers are as under.

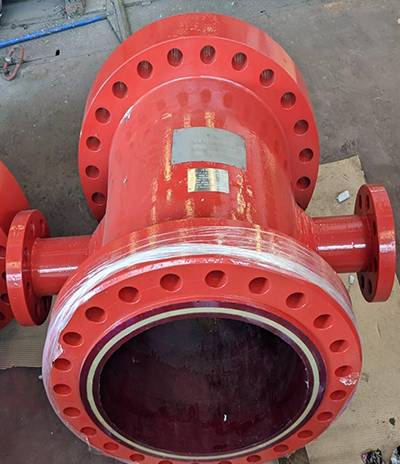

| Bop spools | Repair and recertification of Spacer spools, drilling spools, double studded adapter flange and adapter spools |

| Mud modules, mud manifold and dis-charge manifold | Assessment, weld repair and recertification |

| Coflexip hoses | Repair, recertify, boroscopic condition assessment and recertification. |

| BOP ram blocks | recertification of BOP ram blocks includes wear limit checking, MPI, hardness |

| Dalmage Hammer frame | Site survey, Repair, pre-fabrication, Site inspection for fitment, final inspection with Hammer assembly. |

Diverter System (diverter valve)

BOP spool (Drilling spool)

Coflexip hoses

Hammer frame

Mud modules, mud manifold and dis-charge manifold

Adapter spool